Different Types Of Diffractive Optical Elements (DOEs) for Splitting Light Beams

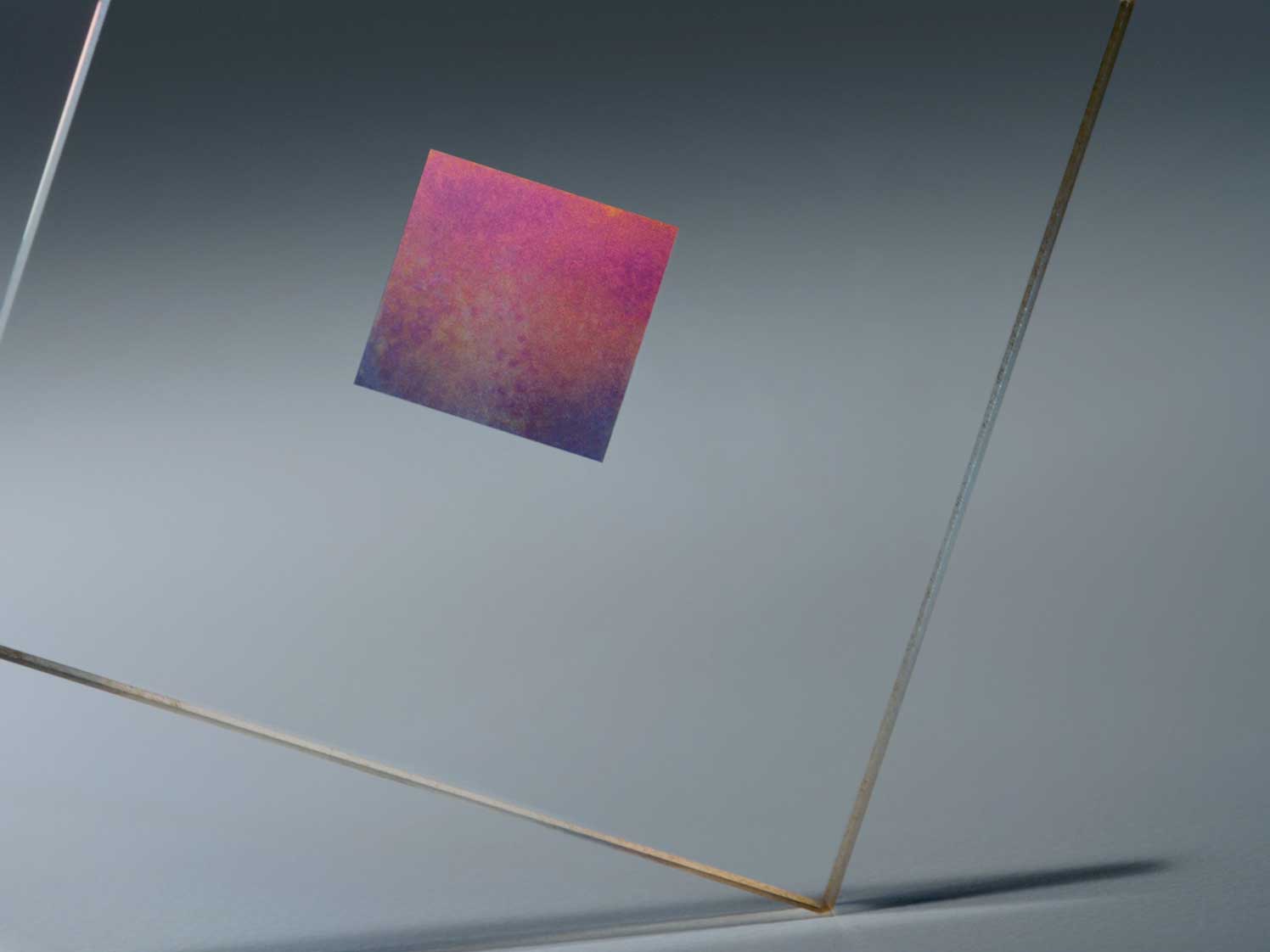

The DOEs from various laser components are used for multi-spot beam splitting to modify beam profiles with the help of high-power lasers. The key benefit of using diffractive optics is you can obtain several beams from just one element. Further, the DOEs can help you obtain precise positioning to create holes at predefined and accurate distances, especially in the cases when proper power separation is necessary.

Before we get down to the range of DOEs available for different beam splitting functions, let’s shed some light on the basic features of a beam splitter.

What is a beam splitter?

A beam splitter is an optical element that divides a single beam of light into numerous ones, each having the same optical characteristics as the parent beam. Depending on the diffractive qualities of the DOEs used, the beam splitters can create either a one-dimensional beam array or a two-dimensional beam matrix. In most cases, the laser beams from a monochromatic light source are used for creating light rays of a specific wavelength and angle of separation.

The diffracted beam finds a wide variety of uses in laser researches and devices like solar batteries, LCDs, 3D motion sensing, beam sampling, perforation, which is used to produce cigarette filters, and in different medical equipment.

Now, let’s turn to the different types of DOEs used for various industrial and commercial applications.

Multi-spot DOEs

These elements are used to diffract a single collimated beam into numerous ones of the same intensity and angle of separation between the light beams. While the one-dimensional beams are used to create beams in a straight line, the two-dimensional ones are used to create a beam matrix.

Multi-focus DOEs

The multi-focus elements are used to create numerous focal points along the optical axis. Used widely in the sensor technology and ophthalmologic experiments and applications, the several focal points can also help optimize results in the material processing industry.

Beam sampling DOEs

These are used for the inline monitoring of high-power lenses. As each output beam has a lower intensity than that of the parent beam, they are significantly used measuring light beams of lower intensities.

High-Efficiency Double-spot beam splitter

Available in the wavelengths of 193 nm and 10.6 μm, the HEDS helps to separate a light beam into two completely identical beams with 97% efficiency. Although the HEDS are quite sensitive to centering, they have little or no effect on the shape of the spot or the overall efficiency of the element.

Wondering where to buy industrial-standard beam splitters or other forms of diffractive optical elements? Get in touch with a reliable manufacturer with years of experience like NIL Technology to help you make the right choice.